With the increasing technology growth around the world, there’s need to have refined products that are well tested and come with Low volume CNC machining for efficiency assurance. The aerospace industry is not different either. So prototyping in the industry means creation of physical or digital models for use in testing and refining before the final machine production.

This means airplane engineers rely on aerospace prototyping to help validate the performance, reliability and functionality of a design. This is also useful to identify and resolve any possible issues before producing the final part or product at scale.

So, prototyping in the aerospace involves a wide range of tools and techniques that will help create accurate representations of the desired designs. Among the different tools include computer-aided design software, simulation & modelling as well as 3D printing.

With everything tool in place, airplane companies are able to avoid costly mistakes and delays thus creating time for development of more innovative and efficient airplane products.

Types of Aerospace Protoyping

Costs for manufacturing airplanes are generally high, so are the costs for preparing protoypes that will simulate the same. Therefore, there are different types of aerospace prototyping that can be used based on the desired results.

These are:

Conceptual Prototyping

This is when the specific product being created is at its early stage, and the manufacturers aim is to have a basic model that can help them validate the expected design. Here the prototypes doesn’t have to be created with actual materials, instead it can be created with simple materials such as foam, cardboards, or anything that can help evaluate the basic functionality of a product.

Preliminary Design Prototyping

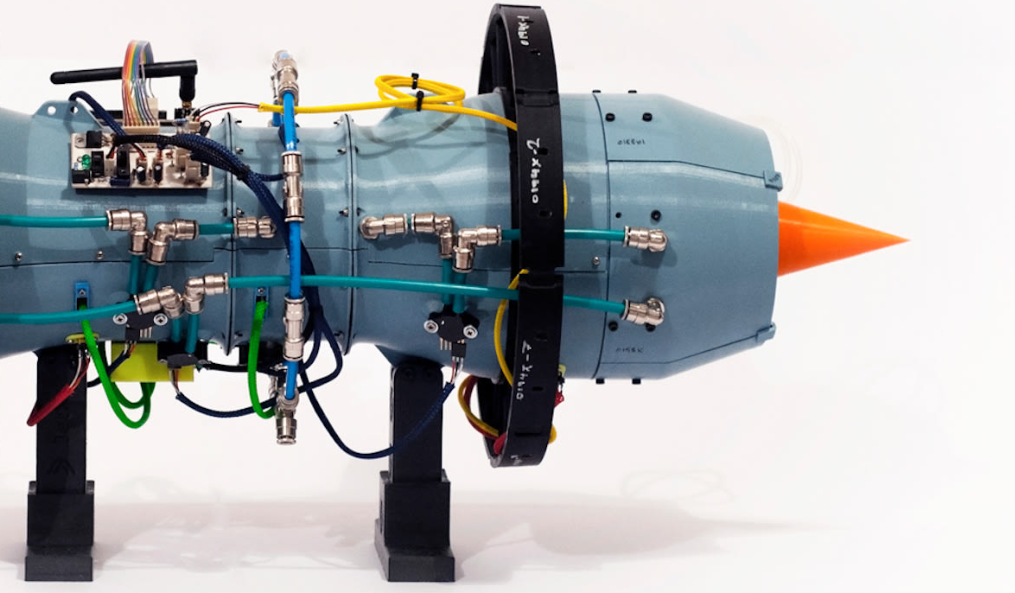

This is the second stage after the design has been validated. Here the manufacturers will mostly use advanced materials and tools such as the computer aided software (CAD) and 3D printing. This stage is often helpful in resolving the design issues before staging the final prototype stage.

Detailed Design Prototyping

This is the final stage where a highly detailed prototypes is designed. The prototype in this stage has to be as close to the final product as possible. It will then be used in different environments similar to where the real product will be used. These prototypes are essential for identifying and helping in the resolving of any final design issues. After this stage the manufacturers can go on and create the final products based on the results received here.

Benefits of Prototyping in the Aerospace design

There are different benefits of creating prototypes, more so considering what a failure in a real product can mean. So some of these benefits include:

Improved functionality and reliability

From the results on the prototypes manufacturing companies have the freedom to create specific products based on the different challenges in real life. Technology is also a significant factor and so the prototypes can guide the production team into creating, unique, functional and highly reliable products.

Enhanced Innovation and Creativity

This process lets production companies in the aerospace industry test various materials. More so, in cases where there have been past failures with certain materials, or in certain extreme environments. So, the manufacturers will be free to test out different solutions until they find a working solution that can be used in the final product.

Conclusion

Prototyping contributes to almost every aspect of the aerospace industry, from the lighting, and interior to the mechanical parts. It is therefore, a necessary process for specialised production and repairs. In the end, its also an important necessity to reduce costs of designing and repairs down the road.